Smarter Motor Monitoring: How Malloy Electric Leverages VFD Data for Predictive Maintenance

Rather than relying on traditional, sensor-heavy methods of nondestructive testing (NDT), Malloy champions a more integrated approach: using the built-in diagnostics of modern VFDs to monitor motor health in real-time. These drives already track key performance metrics like torque, speed, current, and energy usage—data that can be mined for early signs of mechanical wear, misalignment, or power quality issues.

Big News: Malloy major capital expansions in several locations

Sioux Falls, SD (October 30, 2024) – Malloy Electric, a corporation based in Sioux Falls, South Dakota, announces a significant capital expansion to several locations. The expansion includes acquiring an additional horizontal boring mill to complement the existing Johnford boring mill for the Dakota Dunes location. The machine duo effectively answers the growing market need for more extensive above-NEMA frame motor service up to 20,000 HP as well as complimentary major mechanical apparatuses.

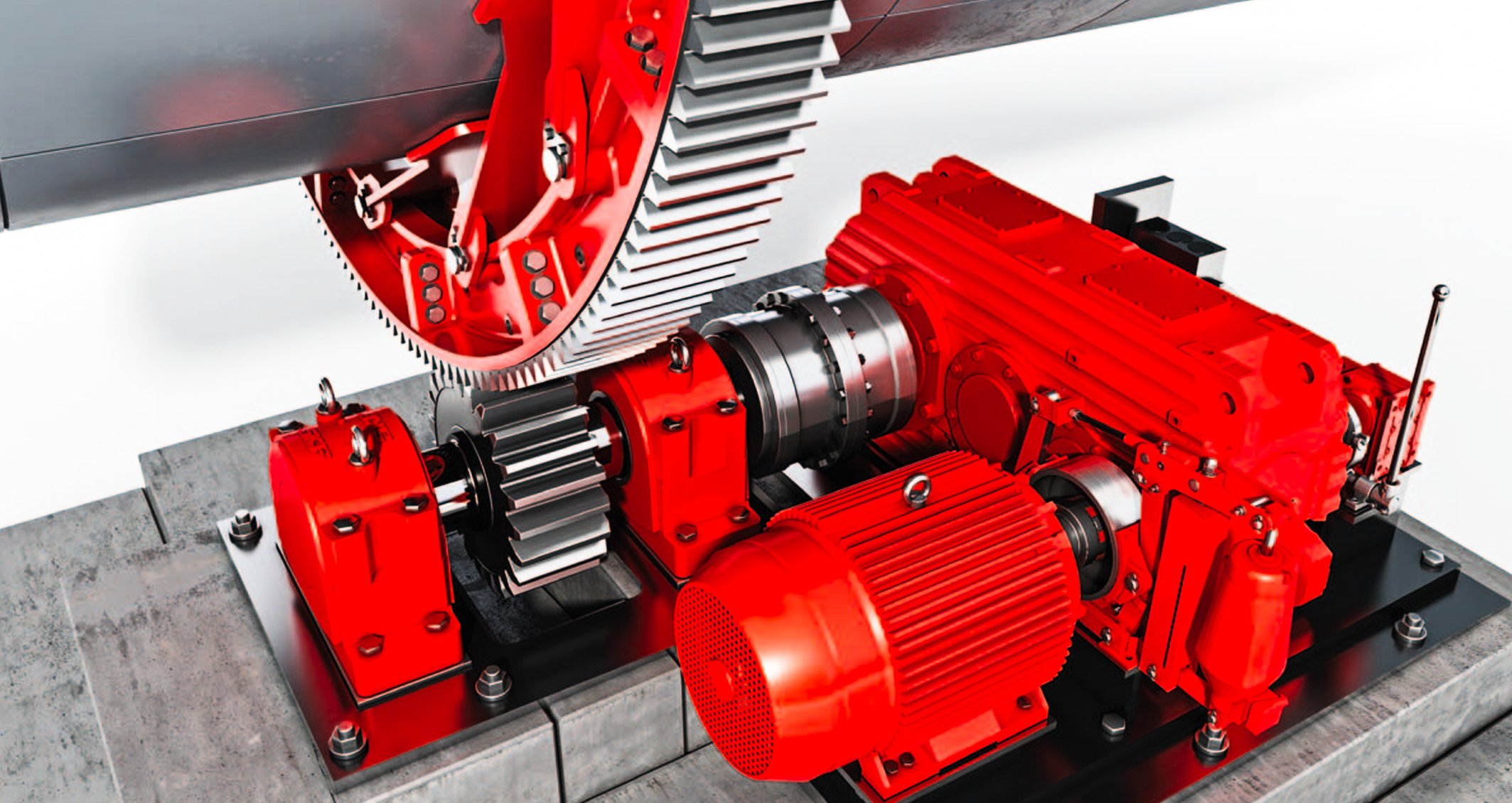

Simple Steps to Gearbox Inspections

Maintaining the efficiency and longevity of an industrial gearbox is crucial for minimizing downtime and maximizing productivity. While it may seem daunting to shut down operations for an inspection, addressing potential issues early can save significant time and money in the long run. This blog post will guide you through the essential steps of inspecting and maintaining your industrial gearbox, ensuring it remains in optimal working condition.

Big News: Malloy becomes an exclusive member of AGMA

For Immediate Release: Malloy Electric, a corporation based in Sioux Falls, South Dakota, renowned for its expertise in the industrial controls, electric motors, and power transmission sectors, becomes an exclusive member of The American Gear Manufacturers Association (AGMA), further expanding its investment in gearing application, service, and repair in the Midwest.

Gearbox Vs. Gearmotor: Clearing up the Confusion

When it comes to industrial machinery and equipment, understanding the difference between a gearbox and a gearmotor is crucial. These components play a significant role in the operation and efficiency of various systems, but many people often confuse the two. In this article, we will delve into the definitions of gearbox and gearmotor, explore their differences, and highlight the benefits of using gearmotors in maintenance operations. Whether you are a maintenance supervisor dealing with equipment breakdowns or facing time constraints, this article will help clear the confusion surrounding these essential components.

Big News: Malloy Joins Forces with SEW-EURODRIVE in new strategic partnership

For Immediate Release: Malloy Electric, a corporation based in Sioux Falls, South Dakota, renowned for its expertise in the industrial, water, and wind sectors, joins forces with SEW EURODRIVE, a global market-leading specialist in drive and automation technology, for a major Engineering, Services, and Sales Initiative across the Midwest.

Solving Equipment Reliability Issues with Comprehensive Above NEMA frame Motor Upgrades

When it comes to industrial plants, equipment reliability is paramount. Downtime can result in significant financial losses and production delays. One of the critical components in ensuring reliable plant operation is the motors that drive essential processes. Large electric motors are often the workhorses of industrial facilities, but as technology advances, older motors can become a liability. In this blog post, we will explore the benefits of upgrading to high-efficiency motors, the seamless integration of drop-in replacements, advanced features for improved reliability, achieving long-term cost savings through energy efficiency, and custom solutions for unique challenges in plant engineering.

7 Steps to Successful Installation of Motors

Proper installation and maintenance are essential to ensure the reliability and longevity of your electric motor. Electric motors are crucial components in various industrial and commercial applications, and any breakdown can lead to costly downtime.

Popping off motor nameplates

During a recent trip, a disturbing discovery was made in the local motor repair industry.